CORECOMPETENCIES

Our team continually researches the latest developments in battery chemistries, cell design, upgrades our testing capabilities, and enhances manufacturing techniques by developing new methods and utilizing innovative resources. We understand that no universal solution exists in battery chemistry. For this reason, we pride ourselves in cultivating innovative design and manufacturing teams to optimize your battery solutions.

DESIGN AND ENGINEERING

Qualifications

- Domestic & International design expertise

- Ultrasonic welders for plastics assembly

- Highly effective & timely technical advice to keep your projects on schedule

- Performance Verification Testing Services available

- ISO-9001 Certified

Chemistries

- Alkaline (ZnMnO2)

- Lithium (Li-Ion, Li-Poly, LiFePO4, LiMnO2)

- Nickel Metal Hydride (NiMH)

- Nickel Cadmium (NiCD)

- Lithium Manganese Dioxide (LiMN02)

- Sealed Lead Acid (SLA)

- Deep Cycle Sealed Lead Acid

- Silver Oxide (ZnAg20)

Global Relationships With Leaders In Battery Power

ZEUS is synonymous with strength. As the leading custom battery pack designer and manufacturer in North America, our organizational strength allows us to ensure the supply of any battery chemistry in all sizes and configurations necessary to fit our unique customer’s requirements.

Designed In-Product Quality

Our high-quality battery packs begin with well thought-out design.

We carefully consider and evaluate each customer’s requirements to establish the safest, most cost effective battery solution to meet our customers needs. Our team has over 100+ years of working on superior battery designs. Making ZEUS expertly qualified to provide the highest-quality battery solution for each of our customer’s applications.

We are committed to providing our customers with the best in Cell & Battery Assembly Solutions. Our equipment and quality control initiatives allow us to produce top-tier products at competitive prices.

SOFT PACKS HARD PLASTIC ENCLOSURES

Materials offered:

Steel, aluminum, impact-resistant plastic, PVC shrink wrap, fiberglass, and more.

Accessories:

Enclosures are equipped with belt clip, hand straps, and desk or wall stations.

Applications:

Barcode scanners, measurement, control products, telecom, and data.

Our customizable, contoured battery pack enclosures are built to the customer’s exact specifications, designing packs for a variety of industries and hand-held devices. ZEUS custom battery pack enclosures are cost-efficient and lightweight, while still providing maximum structural integrity and protection. We provide affordable domestic and offshore tooling options for rapid prototyping and production.

The ZEUS Battery team designs prismatic or pouch (soft-pack) batteries to support a variety of lithium ion applications and help optimize packaging efficiency at the battery level. ZEUS Battery Products provides a variety of compartment styles, including the following options.

- Opening for field replacement by the end-user

- Opening via separate lid that is molded to the plastic to prevent user replacement (OEM replaceable).

- Designed specifically for applications in which frequent or daily charging occurs, requiring nickel-plated spring contacts.

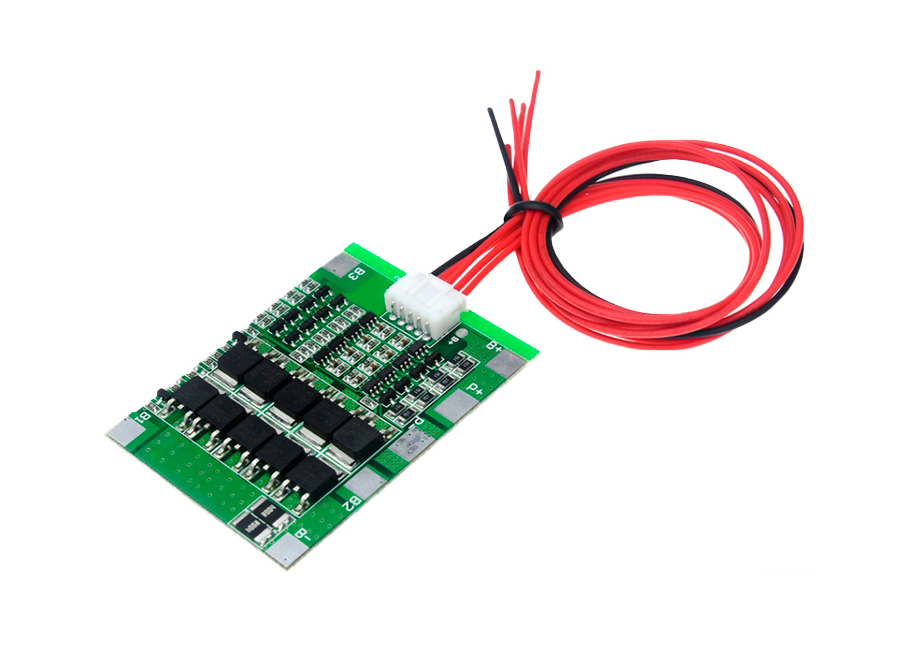

BATTERY MANAGEMENT SOLUTIONS

The Battery Management System (BMS) functions as the “brain” of the battery pack. It measures and reports crucial information for the operation of the battery at the cell & pack level; monitoring state of charge, state of health, protection and wide range of operating parameters.

In its simplest form, a BMS is a Protection Control Module (PCM). A PCM is normally embedded in the battery or battery pack and prevents cells from over-charging and over-discharging conditions.

Battery protection circuits have two electronic switches known as MOSFET’s or semiconductors used to switch electronic signals on or off in a circuit.

Battery fuel (gas) gauge ICs measure battery current, voltage and temperature to find state-of-charge and more. These parameters help control a battery pack performance on the system level to ensure efficient functionality.

Overwhelming increases of portable end-user applications in wireless, computing, consumer, medical, industrial, and automotive markets make battery management solutions vital for today’s markets. This demand for greater reliability from battery-powered systems, ZEUS helps ensure the highest product safety through implementation of chargers that protect batteries in every operating condition.

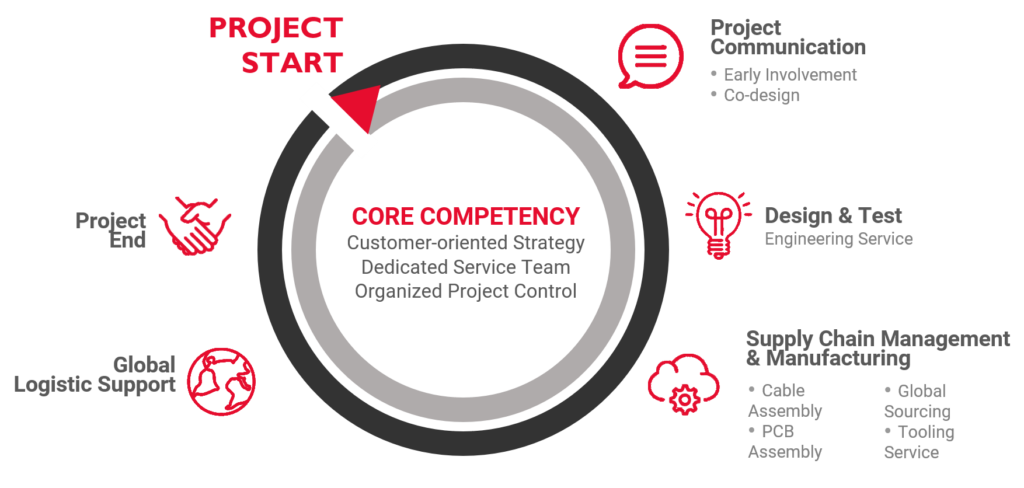

Program Management

Our program management service consists of (3) core strengths which provides our customers with complete program support from start to finish.

Design Analysis:

We interface with our customers / design firms through conference calls as well as on-site appointments with Sales and Engineering teams to define the overall project scope. ZEUS provides complete mechanical and electrical battery solutions to assure the requested objectives are met. We carefully consider and evaluate each customer’s requirements to establish the safest, most effective battery solution.

After finalizing the design, ZEUS offers the best option for our customers to select and move into the sampling stage. Each prototype is tested according to the customer’s specific criteria prior to manufacturing in volume at one of our global manufacturing sites.

Development:

We develop custom battery pack configurations and assist with qualification batch samples for submission to independent testing agencies. ZEUS team members will aid with creating an overall product launch schedule to help our customers bring their product to market in a timely manner. All ZEUS Battery products are subject to stringent quality control processes throughout each step of production.

Delivery:

KanBan / Just in Time / EDI inventory and consignment programs are available to minimize customer inventory levels and buffer against fluctuations in demand. ZEUS Battery Products consistently maintains an on-time delivery rate of more than 99%.

AGENCY CERTIFICATION

Disclaimer

The information contained in this website is intended to provide readers with general awareness of available battery related regulations and does not constitute legal advice. The most current actual regulations and standards in their original language should be reviewed for all business, legal, and product compliance purposes.

Safety Testing for Lithium Batteries

The United States and other international organizations highly regulate the transportation of lithium cells and batteries. The following is an summary of governing agencies and their certifications.

Shipping

Shipping Lithium Batteries

All lithium batteries must pass section 38.3 of the UN Manual of Tests and Criteria (UN Transportation Testing). As they are considered hazardous materials, lithium batteries are subject to regulations. Transportation rules and methods will also vary, depending on the each design’s power needs and whether the lithium battery is primary or rechargeable.

Shipping Prototypes

Only upon passing section 38.3 of the UN Manual of Tests and Criteria (UN Transportation Testing), can a lithium battery pack be considered a production unit. All prototypes are required to be shipped in Class 9 packaging and enclosed in non-combustible, non-conductive packaging material. Additionally, prototypes may only be transported via ground methods and the shipper must be HazMat-trained.